It looked like it had taken a bit of a tumble while in storage, so I'm approaching it as if it's inoperable but remain cautiously optimistic.

That'll hammer right out...

I can image people recoiling in horror at the condition. I think some proper wood panels may be in order once electronics and mechanicals prove serviceable.

I am at present awaiting the arrival of tape, by the time it arrives I will have exacted a brute force fix to this take up side idler arm.

The (presumably) original roller was about the consistency of Play-Doh™, and absolutely useless for anything beyond making a mess. I bagged it up and sent it to Terry's Rubber Pinch Rollers and Wheels for rebuilding.

Terry does good work. Here's the returned Otari roller posing with the Tascam 34 roller it travelled with in April of 2010.

Here's the roller installed on the machine fresh out of storage, I will be pulling it and washing it in mild soap and water to eliminate the storage film.. along with a rigorous cleaning of the rest of the deck.

The headstack carries a JRF Magnetics relap sticker. I've seen a thread on gearslutz in which someone is questioning the condition of a similar looking stack, also carrying a JRF sticker. See, the contact edge to tape appears to be a flat as opposed to convex plane, and at first impression it looks like the tape has cut a saddle and the heads are shot.

However, the polished "saddle" extends above and below actual tape path as seen here indicating intentional machine and polish. So with luck I've got a few more hours on the heads.

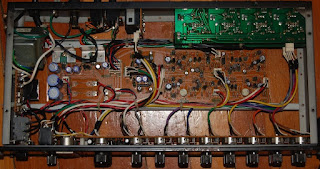

I expect to pull and recap these channels, once I'm through recapping the mixers (one of which was partially disassembled last night, which is a post for another day). The tape and take up reel that are in transit will arrive prior to electronic work, so I expect I'll get an earful of the electronics here prior to recap. Which, better judgement aside, will factor in to prioritizations..

The logic circuits, front panel switching and transport all appear to be in good condition.

The 3 & 6 input connectors may receive a little of the aforementioned brute force repair as well.

Not striving for minty fresh here, just functionality.