Building a rotating cradle to allow on point unrestricted tilting of my video camera for deployment in video feedback.

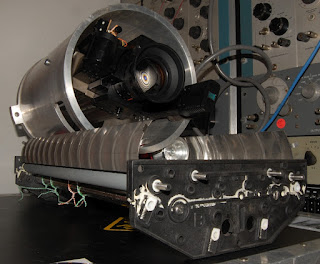

This is the build up to this point, camera is mounted within an aluminium drum riding on rollers. I understand the drum is an out of spec helicopter part that I salvaged from a scrap bin, the rollers are from an old color photograph processing machine with One Drop yo-yo parts elevating the drum (and all the non-round elements) clear of interference.

I should have taken a picture of this prior to modification, it'll have to wait until I grab another one (I believe there are three of these: developer, stop & fix) to photograph.

My initial visualization of the mounting of the camera was a lot more elaborate than this, which amounts to a 1/4" 20 tpi screw through a shaped woodblock into the tripod mount of the camera. I've still got to remove some material from the woodblock as it places the camera just a touch high of center.

This was a problem at first. I had initially been designing around the solid roller support depicted in the baseplate picture above. My plan was to countersink the hardware into the sidewall of the drum, but while the drum is indeed quite thick (roughly 1/4") there would not be nearly enough material remaining to carry the weight of the camera.

Furthermore, each solid roller rode on a couple rubber rollers that tilted outward due to limiting myself to precast positions in the plastic end plates (that is to say, the outermost roller is lower than the inner). This resulted in the solid roller wanting to walk off the supports when the drum was rotating toward it.

I installed the shrouds on each side to eliminate the walk off problem, but the solid rollers would still shift, which resulted in the entire assembly moving off center as well running contrary to the entire point of building a centered rotating mount in the first place.

So I had a two tier puzzle that needed resolving: A) I needed a gap that will allow the button head of the hardware to pass the rollers without being a disruptive speed bump, and B) I needed a simple and unrestrictive method to fix the larger bearing rollers in place.

Both puzzles were solved by ousting the heavy solid bar, and wiring up One Drop yo-yos to the structural bar below the rollers.

Plenty of gap to allow that screw head to pass.

I still need to reduce the size of the wooden shim, but it's close enough to center to work as is at a live video show this coming Friday. Extended plan includes motorizing the drum and incorporating CV response to the motor driver.