HELLO!

My, my, it has been a while.

The fault is entirely mine. I've been immersed in the doings of Rochambeau Musical Apparatus for the past couple/few years now and it has sort of locked my time away from this particular avenue of sharing. While I will admit that what I am doing with RMA is in and of itself blog-worthy from a content point of view, it is also a deeply personal journey through mis-applying engineering, empirical education, and general mayhem and I have decided that my process functions better outside the spotlight and on my terms.

I want to stress that this is not due to overt secrecy; if anyone has any questions regarding any of the RMA designs or specific builds I should be somewhat easy to find.

At any rate, I have a back log of personal projects still and I will endeavor to publicize them when I feel doing so adds value to our pool of knowledge. Now without further ado:

The Akai MPC2000xl I purchased new in the spring of the year 2000 had lost function of the note variation slider. This appears to be, based on my perfunctory google search, a relatively common problem. Replacement parts are easy to find through branded supplier sites, but I'm a skinflint so when I happened upon a webpage that outlined opening up the slider and cleaning it out I naturally took that road first.

Are there twigs in there?

Full disclosure: my studio environment has at times been substandard in regards to environmental control. We're talking basements, uninsulated sheds, and a warehouse space in which the only source of heat was a tube amp and an engine block cooling off after my drive home from work. Swings in temperature and humidity are hard on gear, and the necessity of fixing stuff has delivered me to where I am today. Anyway, the slider contacts were indeed swamped with muck. A little isopropyl gently applied was in order...

..ah. Well then. It's an easy task to clean metal; it's quite challenging to grow it back into shape. And no, bending the corroded tines of the wiper outward a little bit in order to regain contact proved fruitless.

So, as I mentioned before, you can simply punch a couple keywords into a search engine and locate a specific replacement for this part with ease. I found them ranging from $10 to $15 USD before shipping, which, while far from outlandish did not strike me as the most effective solution.

I regularly order parts from Mouser for RMA, so it stood to reason that by looking for the part in generic terms I could skip at least one generation of mark-up. The criteria is 10K linear dual gang 45mm throw with a particular PCB footprint. I found my match here at Mouser for $1.83 before shipping.

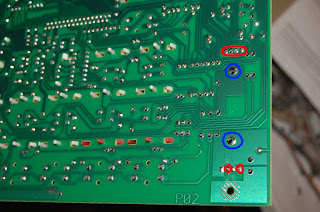

Here's a PCB side shot indicating the solder joints that need to be removed for extraction. The blue pads are structural and two of the lower pads connect to nothing and can be ignored (at least in my machine).

Removal of the failed component was a breeze with my iron and a plunger type solder sucker.

Look at that! A single sided PCB with through hole wire jumpers.

New part drops right in, and soldered right up.

It's alive!

I didn't go into tear down of the MPC because while I am guilty of not having looked it up, I'm ASSuming there are numerous excellent information stores you can find regarding that. I do need to qualify my fix with the following:

THIS IS NOT A DEAD STOCK REPLACEMENT.

Functionally my machine works again, but the slider I used A) will not accept the stock slider cap (I may drill my cap out to attain a fit, but this is risky because the shaft of the new slider is larger in both non-height dimensions and there is not a lot of material to work with) and arguably more important B) the new slider has a center detent.

Since this is my machine I do not mind the center detent (in fact, I kind of like it) but I should note that at centered position my machine reads a +8 in the +/-120 range, so electrically it is not centered when physically centered.

For those reasons I would recommend the OE parts for client based work, but I'm happy with my fix.

No comments:

Post a Comment