A little internet investigation indicates a likelihood that this is due to a failed back-up battery, a Tadiran TL5101. This was built early 1990, so it is reasonable to assume the battery is toast.

The above sentiment applies to the entire family here. I'm going to crack the case on each of these to confirm that the TL5101 package is the same on all, as I really hate having to improvise with batteries when an easier option exists. For what it's worth, there are three available packages of TL5101, and a variety of PCB revisions for the Alesis units.

While I have the trio together it makes sense to do a quick run through of each and earmark attention areas I should address while the case is cracked and I'm changing the battery.

The MMT-8 was a bad amp room unit, so my expectations were low. Powers right up, logic responds without readily apparent glitches and the pad response is very crisp. This must have been in the boneyard due to a misplaced wall wart.

The HR-16 was purchased used in 1998. The pads are in complete need of rework, this unit is almost unusable as is.

The HR-16B was a trade a year or two ago, pads require a firm hand but respond under pressure and the volume and data sliders had been sheared. It also needs a back-up battery.

The axial 1/2AA package is standard across all three examples in my possession. Inorganic.

I had envisioned some level of nuisance in regards to the sliders (mind you, I have not yet narrowed them down to a part number and learned of availability).

Any concern I had regarding remove and replace is unfounded however.

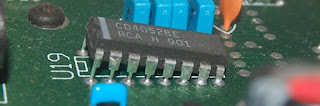

Concern over the Alesis QC is another story, though in their defense this unit has run for over two decades (it could buy beer if it was so inclined) so the unseated IC isn't detrimental, it does however stick out like a sore thumb.

Conductive rubber keypads are, in my opinion, a tool for post warranty failures. Perhaps I have never happened upon the right mix of chemicals to replenish the conductive nature, and I've always been wary about trying a conductive paint for fear of adhesion failure making a huge mess. So it looks like aluminium foil to me. I'll do a bit more research before actually performing this irreversible modification, but if my other option is trying to punch through the PCB traces I'll clad these nipples in foil at the drop of a hat.

Keypad modification sounds a lot more pleasant than fabbing another interface PCB.

Here's where the velocity information comes from, a quartet of piezo discs on the backside of the drum-pad section.

Motherboard time:

MMT-8

HR-16, looks like a Rev. A in referencing the service documents.

HR-16B, service docs indicate this is a Rev. AQ, so I'm going to climb out on a branch and speculate that the revision sticker at lower right refers to software, not hardware.

3 comments:

I haven't tried this yet, but I've bought replacement keys from this guy before, so he might be worth a shot.

$26 for 75 stick-on contact pads that he says he has had great luck with so far.

http://sounddoctorin.com/synthtec/parts/key.htm#polycontacts

Hmm, interesting angle. Worth a shot if the preliminary cleaning does not take. I notice he's put a hold on orders until further notice due to some paypal foolery and recall reading a less than stellar write up about the guy on Barbour's blog, but hey, if it works it works.

For whatever it is worth, the conductive-glop-on-rubber-button hing is all over telephones and some of the phone supplier guys have come up with repair methods -- Mike Sandman in Chicago is the one I know about: http://www.sandman.com/button.html

Post a Comment